Across our portfolio, we offer products that support a sustainable lifestyle. Reusable water bottles by Contigo® and bubba® help to reduce single-use plastic consumption. Rubbermaid® and Sistema® food storage containers and FoodSaver® vacuum sealers keep meals fresh longer and help to reduce food waste. Coleman® tents and sleeping bags enable nature enthusiasts to connect with the great outdoors. Our Rubbermaid Commercial Products® solutions support sanitation, hygiene, proper waste management and recycling.

Sustainable Product Design

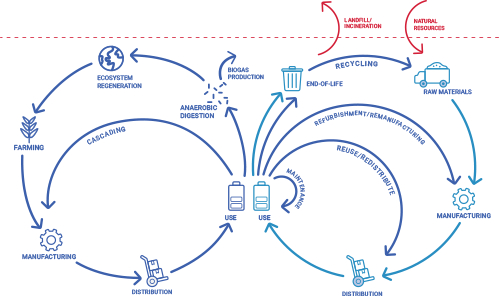

We consider sustainability at every stage of the product development process, from ideation through product launch, leveraging a Design for Sustainability framework. This framework helps our teams find ways to meet consumer needs with less environmental impact, identify materials that reduce natural resource depletion, make design choices that extend a product’s natural life, and develop with circularity in mind.

Sustainability Strategies For Product Design

Product and Packaging Sustainability

2025 Packaging Goals

|

2025 Goals |

Progress* |

|---|---|

|

Eliminate the use of Polyvinyl Chloride (PVC) and Expanded Polystyrene (EPS) in all packaging |

93% EPS-free |

|

Source 100% of our direct-sourced paper-based packaging from certified, verified or recycled sources |

97% globally 98% North America |

|

Use at least 20% non-virgin (recycled content) in plastic packaging for Newell manufactured goods |

13% |

*The progress for our packaging goals is based on a 2024 survey of 2023 data provided by our major suppliers.

- The Marmot® team increased the use of sustainable materials in their garments, including responsibly-sourced down, bio-based yarns and bluesign-APPROVED™ fabrics, which are manufactured to strict environmental and safety standards. By the end of 2023, 36 percent of Marmot’s apparel fabrics were bluesign-APPROVED™, and 49 percent were made with recycled content.

- The EXPO® binder pack was redesigned to replace the PVC used in its packaging with a fully paper-based solution. This change eliminated the use of 13.77 metric tons of PVC in 2023 alone while enabling our packaging to be considered curbside recyclable in the U.S.

- DYMO® moved its Direct Thermal Label, LabelManager, and Embossing printer packaging from PVC to polyethylene terephthalate glycol. It also improved the curbside recyclability of the pack, complemented by on-pack sortation instructions across regions.

- Paper Mate® 's new Kilometrico pens, an innovation launched in our EMEA and APAC markets, contain 80 percent recycled product materials, plastic-free packaging and a promise to write for at least a kilometer in distance. They use paper-based packaging as an alternative to the plastic pouches in the pen's standard version.

- DYMO's paper products are made of materials certified by the Forest Stewardship Council® (FSC) and other controlled sources. FSC certification ensures that products come from responsibly managed forests that provide environmental, social and economic benefits. Additionally, DYMO’s consumer packaging is made with up to 80 percent recycled materials, and as of 2023, machine packaging is now made of at least 70 percent recycled paper.

- Sistema® ’s products became more sustainable in 2023 with a new range of food storage containers made with at least 35 percent ocean-bound plastic. Ocean-bound plastic refers to waste that has been improperly disposed of on land or waterways and is collected, cleaned, and refined for recycling. The reusable bottles and food containers reduce the need for single-use plastics and help keep existing single-use plastics out of the ocean.

Consumer Safety and Satisfaction

Consumers trust and rely on our brands, and we are committed to providing them with safe products through rigorous safety standards and testing. While potential safety concerns differ greatly from one product to the next, product safety is a collective effort. We have a cross-functional team that oversees product safety and ensures that safety insights, regulations and advancements in technology are shared across businesses.

Product Safety Collaboration and Oversight

We conduct internal testing and safety evaluation of products to proactively identify potential issues and ensure we are compliant with regulations where we sell our products. Many of our products also receive third-party safety audits and testing. We use our Design Failure Mode and Effect Analysis (DFMEA) tool to identify potential risks in new products. Products intended primarily for children, go through a third-party compliance audit at least once annually, and we certify our Graco® and U.S. baby brands to the Juvenile Products Manufacturing Association (JPMA) standard.

Addressing Chemical Substances and Practices of Concern

Our products comply with all applicable laws and regulations in the markets where they are sold, including those relating to chemical substances. Each of our businesses maintains a restricted chemical substances list tailored to the product or product category and published chemical watchlists of industry associations. These requirements incorporate applicable international, federal, state and local laws. As regulations change, we monitor and update our restricted chemical substance lists.

Stories About Our Products

-

January 14, 2025Looking Back at 2024: Our Favorite Innovations